How to tackle buying lifting equipment? (II)

The theoretical basis regarding the working group classification has helped the prospective equipment manufacturer to have a clearer criteria for the design of an appropriate equipment. However, this does not apply to the prospective client, (except for the most experienced and knowledgeable ones) as they might be limited about the knowledge of the rules to be applied.

With regards to the concept of classification, class, or group, we are going to look into the main differences among the rules. We cannot ignore the fact that the differences can be quite notorious even if they have the same starting point and eventually they mean the same but when put into practice there are important differences.

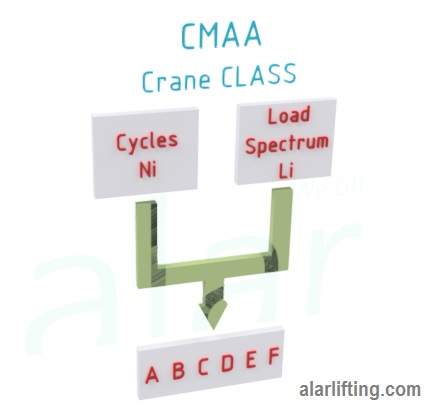

CMAA standard : Sets up a classification for the entire crane, without making distinctions between mechanisms and structure. Types: A,B,C,D,E,F

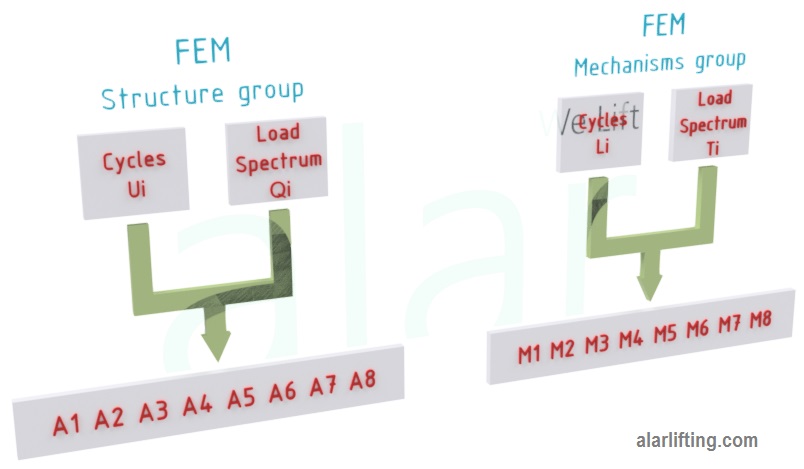

ISO/FEM standard : Sets up a classification for the mechanisms and a different one for the structure. These two do not have to match but in practice they are considered equal in order to simplify.

Structure classification: A1, A2, A3, A4, A5, A6, A7, A8

Mechanisms classification: M1, M2, M3, M4, M5, M6, M7, M8 (1), M8(2), M8 (3).

Standard гост. In concept, they are the same as ISO/FEM

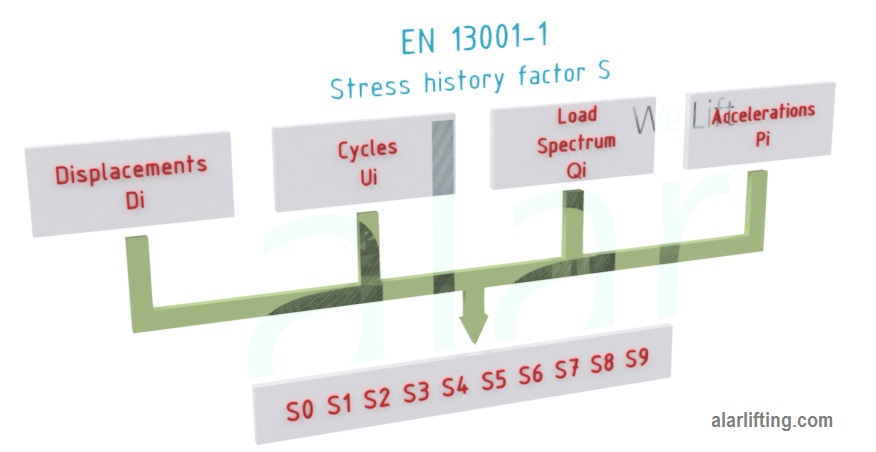

EN-13001 standards: Sets up a classification for EACH ONE of the element of the crane. Each element of the crane needs to be classified with regards to the usage it will have, therefore more knowdledge and means are required from the designer/manufacturer.

This matter will be tackled on a separate article due to its great importance.

With regards to this last note, we need to emphasize that in reality the different elements of the crane are subject to different tensions even if they bear the same load.

For example, the estructure of a crane carriage gets directly the strain of the elevation of the load (amplified by the proportinal dynamic rates). On the contrary, the beam is subject to the maximum effort only when the carriage is located in the centre of the beam, therefore, its classification will be a few types below (rarely in the same tension chart).

According to the new standard 13001, the classification has no effect in the verification of the elastic limit (weariness of a cycle). This is due to the fact that the dynamic elements depend on the nature of the system (stiffness, changing activations, direct starters, …..), regardless of its group, which entails a significantly different criteria to the one established by the FEM.

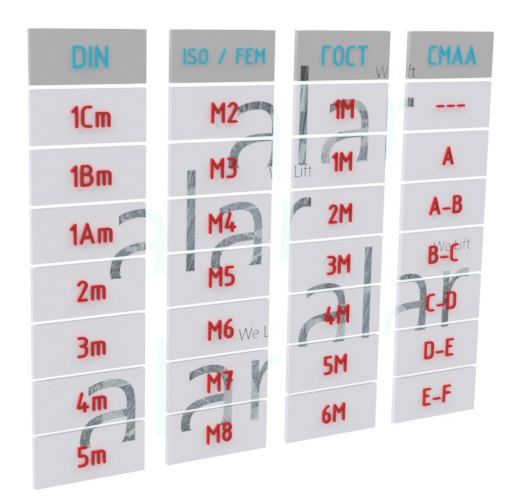

An approximate guidance among the rules would be the following (Please do not take as exact) :

All these concepts will be used as base knowledge for the engineer to initiate the pertinent calculations necessary for the correct measurements of the equipment.

In other fields, for example commercially, this serves as a preliminay guide to classify the crane and as an objective criteria to offer the best value technically.

BIBLIOGRAPHY

FEM-1001-101998. Regles pour le calcul des appareils de levage, cahier 2.

FEM-9511-061986. Classement des mecanismes.

CMMA Specification #70, Revised 1988. Specifications for Electric Overhead Traveling Cranes.

EN 13001-1:2015. Cranes – General Design Part 1: General Principles and Requirements

Comments are closed.